Flanges are essential components in industrial engineering, providing secure connections for pipes, valves, and other equipment. These flat metal discs ensure leak-proof seals, making them vital for efficient and reliable piping systems. As industries evolve, understanding flanges - along with their functions, types, materials, and standards - becomes crucial for enhancing operational efficiency. This article explores the importance of flanges, emphasizing their role in improving system integrity.

Flanges, also known as pipe flanges, are components that connect pipes to each other and serve as connectors between the ends of pipes. They are also used at the inlets and outlets of equipment to facilitate connections between two devices.

A flange connection, or flange joint, refers to a detachable assembly where flanges, gaskets, and bolts work together as a combined sealing structure. When used in piping installations, the term "pipe flange" specifically refers to the flanges employed for connecting pipes, while "inlet and outlet flanges" pertains to those used on equipment.

Flanges serve several essential functions in industrial applications. Primarily, they provide a reliable method for connecting pipes, valves, and other equipment, ensuring leak-proof seals. Flanges also facilitate easy maintenance and inspection of piping systems, allowing for quick disassembly and reassembly without compromising system integrity.

Flange

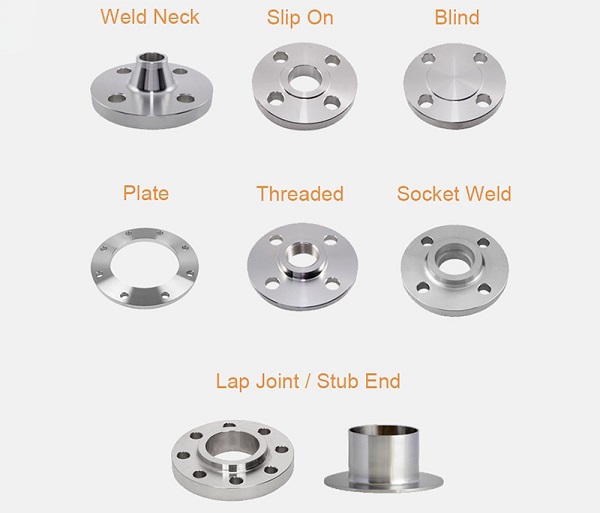

There are holes on the flange and bolts make the two flanges tightly connected. The flanges are sealed with gaskets. Flanges can be classified based on their design and connection method, which is essential for selecting the right type for specific applications. The primary types include integral flanges, threaded flanges, flat welding flanges, butt welding flanges, loose flanges and flange covers.

Integral flanges are formed as a single piece with the pipe or equipment. This design offers high strength and durability, making them suitable for high-pressure applications. They eliminate the risk of leakage at the joint since there are no additional components.

Threaded flanges have internal threads that allow for easy connection to pipes with matching external threads. They are commonly used in low-pressure systems and are valued for their straightforward installation and disassembly. However, their use is limited to applications where leakage is not a critical concern.

Flat welding flanges feature a flat surface designed for welding to the end of a pipe. This type provides a strong and permanent connection, ideal for high-pressure environments. The flat design allows for a smooth transition between the flange and the pipe, minimizing flow restrictions.

Butt welding flanges are designed to be welded directly to the pipe ends, providing a robust, leak-proof connection. They are often used in applications requiring high strength and durability, such as in heavy machinery and high-pressure systems.

Loose flanges consist of two separate parts: the flange body and a separate ring that fits over the pipe. This design allows for easier alignment and assembly, making them suitable for applications where frequent disassembly is needed. Loose flanges help simplify maintenance and repairs.

Flange covers are protective caps used to seal flanged connections when not in use. They prevent dirt, debris, and moisture from entering the system, helping to maintain the integrity of the piping system. Flange covers are essential for ensuring the longevity of flanged connections, especially in outdoor or industrial environments.

By understanding these various types of flanges, industries can select the right flange for their specific application, ensuring optimal performance and reliability in their piping systems.

Flanges are used in pairs, low pressure pipes can use wire connection flanges, and welding flanges for pressures above 4 kg. A gasket is added between the two flanges and then tightened with bolts. The thickness of flanges with different pressures is different, and the bolts they use are also different. When water pumps and valves are connected to pipelines, the parts of these equipments are also made into corresponding flange shapes, also called flange connections.

All connecting parts that are connected by bolts on the periphery of two planes and are closed at the same time are generally called "flanges", such as the connection of ventilation pipes. This kind of parts can be called "flange parts". But this kind of connection is only a part of the equipment, such as the connection between the flange and the water pump, it is not good to call the water pump "flange parts". Smaller ones, such as valves, can be called "Flange Types parts".

Flanges are widely used, and are widely used in basic projects such as industry, shipbuilding, water supply, chemical industry, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire fighting, electric power, aerospace, shipbuilding, etc.

The choice of material for flanges is critical and varies based on the application. Common materials include:

Carbon Steel: Strong and cost-effective, suitable for many industrial applications.

Stainless Steel: Corrosion-resistant and ideal for harsh environments, particularly in chemical processing.

Alloy Steel: Designed for high-stress applications, offering enhanced strength and durability.

Hebei Pipefun Pipe and Fitting Facility Co., Ltd. adheres to various international flange standards, including ASME, ANSI, BS, DIN, ISO, JIS, and GOST. By following these established guidelines, the company ensures that its products meet high-quality specifications and are compatible across different applications and industries.

In conclusion, flanges are essential components in industrial piping systems, performing multiple functions that enhance operational efficiency and safety. By understanding the various types, functions, materials, and standards of flanges, organizations can make informed decisions that improve their operations. Stay tuned to our blog for more insights and expert advice on industrial components.

The company also provides Stainless Steel Pipe, please feel free to contact us if necessary.

To measure flange size, you need to determine several dimensions using a caliper or measuring tape. Start with the outer diameter (OD) of the flange, which is the distance across its widest part. Next, measure the bolt circle diameter (BCD), which is the diameter of the circle formed by the center of the bolt holes. Don’t forget to check the thickness of the flange itself, as this can vary based on application needs. Lastly, measure the diameter of the bolt holes, as this will be important for selecting compatible bolts.

Changing a toilet flange involves a few straightforward steps. First, turn off the water supply and flush the toilet to empty the tank. Once the tank is empty, remove the toilet by unscrewing the bolts that hold it in place and lifting it off the flange. After the toilet is removed, take out the old flange by unscrewing or prying it free from the floor. Install the new flange by securing it to the floor with screws, ensuring it is level. Finally, reattach the toilet by aligning it with the new flange and securing it with bolts, and then reconnect the water supply to test for leaks.

To effectively use a flange plunger, start by positioning it over the drain, ensuring that the flange part creates a tight seal around it. Begin by pushing down gently to create suction, then pull up quickly to break that suction. Repeat this motion vigorously for about 20 seconds, which helps to dislodge any clog that may be present. After plunging, flush the toilet or drain to check if the blockage has been cleared. If needed, repeat the process until the drain flows freely.

Copyright © Hebei Pipefun Pipe and Fitting Facility Co., Ltd. All Rights Reserved | Sitemap